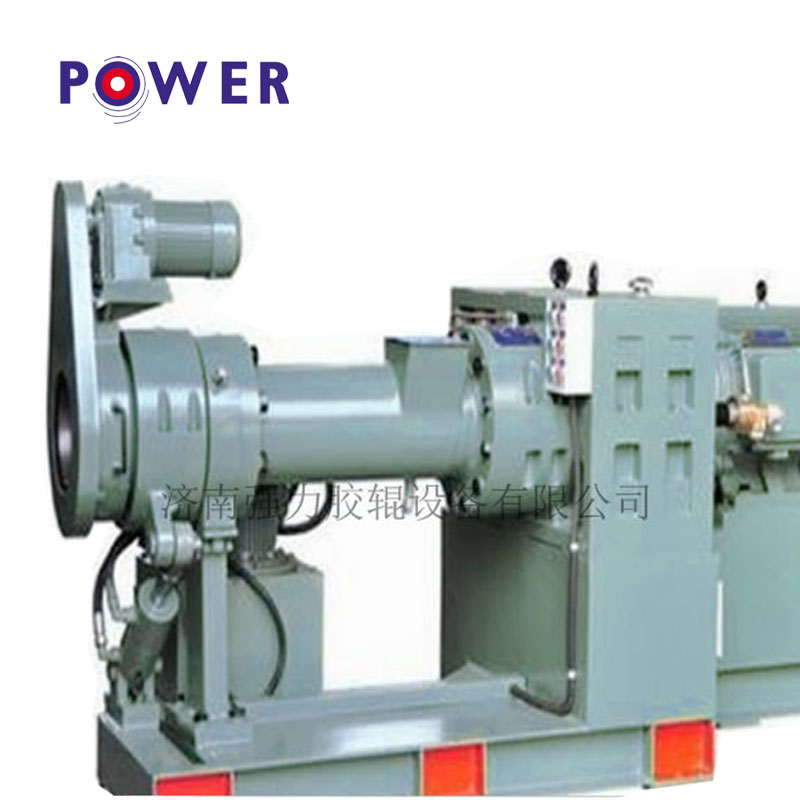

Isihlungi senjoloba / strainer yenjoloba

Ukukhetha isihlungi senjoloba

1

Isici: Kulula ukuhlanza, kungakhipha isihlungi se-mush esingu-200, ukuphuma okukhulu.

2

Isici: Uhla olukhulu lwe-Rubber Compact lungahlungwa.

1) Uhlobo lwesikulufa esisodwa:

Uhlobo olujwayelekile lwesikulufa esisodwa - lufanelekile ku-compound phakathi kuka-25-95SH-a, kepha hhayi nge-rubber ephezulu yokubona irabha, njenge-silicon njll.

Phopha ukondla Uhlobo lwesikulufa esisodwa - lufanele zonke izinhlobo zeroyimu yerabha phakathi kuka-25-95SH-a, ngisho naku-rubber ephezulu yokubona irabha, njenge-silicon, i-ETC.

2) Uhlobo lwe-Dual-Screw:

Phonsela ukondla ngohlobo lwe-Dual-screw - olufanele zonke izinhlobo zeroyimu yerabha phakathi kuka-25-95SH-a, yebo irabha eliphezulu le-rubber, njenge-silicon, i-ETC.

Faka amandla okudla okubili-isikulufa ngohlobo lwe-TCU - olufanele i-compound phakathi kuka-25-100SH-a, ikakhulukazi elilungele i-Framete Encuive Compact.

| Ipharamitha yokuhlunga ye-dual-screw rubber | |||||

| Thayipha / uchungechunge | φ115 Thayipha | Φ 1230 Thayipha | φ200 Thayipha | φ250 Thayipha | φ300 Thayipha |

| Isikulufa ububanzi (mm) | 115 | I-150 | -Mashumi | 25 | 300 |

| Ukucacisa okucacisiwe | Ibhokisi le-225 gear | Ibhokisi legiya le-250 | Ibhokisi legiya lama-280 | 330 ibhokisi legiya | Ibhokisi legiya lama-375 |

| Isilinganiso-ububanzi besikulufa (l / d) | 6:01 | 1.8: 1 | 2.7: 1 | 3.6: 1 | 3.6: 1 |

| Isikulufa esiphakeme kakhulu (i-rpm) | 45 | 45 | 40 | 40 | 35 |

| Ama-motor Power (kW) | 45 | 45 ~ 55 | 70 ~ 90 | 90 ~ 110 | I-130 ~ 160 |

| I-Power Voltage (V) | I-380 | I-380 | I-380 | I-380 | I-380 |

| Ukukhishwa okuphezulu (kg / ihora) | I-240 | 300 | 355 | 445 | 465 |

| Amandla we-compressor anit | 5P | 5P | 5P | I-7.5P | I-7.5P |

Ukukhethwa kwesilinganiso sobude obude:

1. Uma kunesihlabathi enjoloba, isilinganiso sobubanzi besikulufu kufanele sikhethwe ingxenye enkulu.

2. Ithuba lesilinganiso sobude obude bobubanzi besikulufa ukuthi ingxenye yokusebenza yesikulufa yinde, izinto zepulasitiki zihleliwe, ukuxubana kufana nengcindezi ephezulu futhi ikhwalithi yomkhiqizo ilungile. Kodwa-ke, uma isikulufa sinde, sizokwenza ukuthi irabha lishise, futhi ukucubungula isikulufa kunzima, futhi amandla okukhishwa anda.

3

Izinzuzo zokwanda kobude-ububanzi

1) Isikulufa sicindezelwe ngokuphelele, futhi izakhiwo ezingokomzimba nezisebenza zemikhiqizo zingathuthukiswa.

2) Ukuhlelwa okuhle kwepulasitiki nekhwalithi enhle yemikhiqizo.

3) Khulisa ivolumu ye-extrusion nge-20-40%. Ngasikhathi sinye, ijika elicinisiwe lesikulufa elinesilinganiso esikhulu sobude-ububanzi linomthambeka ophansi, ithambekile eliyisicaba, futhi elizinzile lokukhishwa.

4) Okuhle kokubumba i-powder, njenge-PVC powder extrusion yokukhishwa kwe-tube.

Okubi kwesilinganiso sobude obukhulayo:

Ukukhuphuka kwesilinganiso sobubanzi obukhulayo kwenza ukwenziwa kwesikulufa kanye nomhlangano wesikulufu nomgqomo kunzima. Ngakho-ke, isilinganiso sobude-ububanzi asikwazi ukwanda ngaphandle komkhawulo.

Amasethingi

1. Insiza yokufaka.

2. Inkonzo yesondlo.

3. Kuhlinzekwe insizakalo ye-inthanethi yezobuchwepheshe.

4. Insizakalo yamafayela wezobuchwepheshe enikeziwe.

I-5. Inkonzo yokuqeqeshwa esizeni enikeziwe.

I-6